In the world of firearms enthusiasts and DIY gunsmiths, assembling an AR-15 lower receiver is a common project. To ensure the precision and legality of the build, using a jig is essential. Jigs guide the drilling and milling processes, resulting in a properly functioning firearm. Among the options available, the drill press AR-15 lower receiver jig and the router AR-15 lower receiver jig stand out as popular choices. Let’s delve into the differences between these two jigs and explore their unique advantages.

Drill Press AR-15 Lower Receiver Jig: The Path of Accuracy

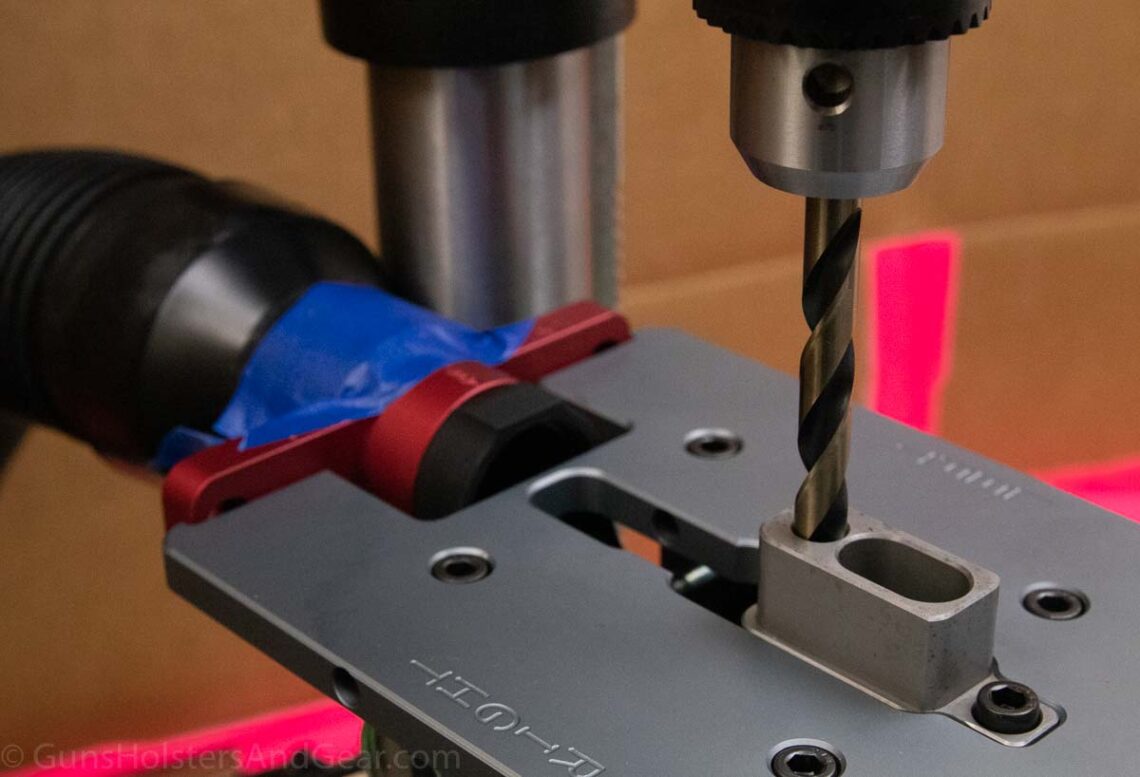

A drill press AR-15 lower receiver jig is designed to assist in drilling the necessary holes for the hammer, trigger, safety selector, and pins in the lower receiver. It offers precise alignment and depth control, ensuring that the holes are drilled accurately. This jig is particularly appealing for those who have access to a drill press and are comfortable working with it.

Key Features of Drill Press AR-15 Lower Receiver Jigs:

- Stability and Accuracy: The drill press jig securely holds the lower receiver in place, minimizing the risk of misalignment during the drilling process. This results in holes that are aligned exactly as required for proper functioning.

- Drilling Depth Control: Many drill press jigs allow for adjustable drilling depths. This feature is crucial in ensuring that the holes are drilled to the correct depths, which is essential for the proper placement of components.

- Simplicity: Using a drill press jig is relatively straightforward, especially for individuals familiar with drill press operations. It involves a step-by-step process that can yield accurate results with proper attention to detail.

Router AR-15 Lower Receiver Jig: Precision Meets Versatility

The router AR-15 lower receiver jig takes a different approach, utilizing a router to mill out the fire control group pocket, trigger slot, and safety selector hole. This method allows for more intricate shaping and customization, catering to those who want to add unique features to their lower receivers.

Key Features of Router AR-15 Lower Receiver Jigs:

- Complex Machining: Router jigs enable users to achieve more complex shapes and contours in the lower receiver. This is particularly useful for those who want to create personalized designs or incorporate non-standard features.

- Customization: Router jigs offer the flexibility to create customized lower receivers with unique patterns and designs. This appeals to individuals seeking a firearm that stands out from the standard options.

- Repeatability and Precision: Just like with drill press jigs, router jigs ensure precision and repeatability. Once set up correctly, router jigs can be used to produce consistent results across multiple receivers.

Choosing the Right Jig: Factors to Consider

Selecting between a drill press AR-15 lower receiver jig and a router AR-15 lower receiver jig depends on several factors:

- Skill Level: If you’re more experienced with machining and routing, a router jig might be appealing due to the creative possibilities it offers. However, if you’re new to firearms assembly, a drill press jig might be a more straightforward choice.

- Tools: Access to tools like a drill press or router is a crucial consideration. Using a drill press jig requires a drill press, while a router jig necessitates a router with appropriate bits.

- Purpose: Consider the intended use of the firearm. If precision and adherence to specifications are paramount, a drill press jig might be the better option. If customization and creativity are key, a router jig might be more suitable.

In conclusion, both the drill press AR-15 lower receiver jig and the router AR-15 lower receiver jig have their merits. The former emphasizes accuracy and simplicity, while the latter offers versatility and customization. Your choice should align with your skill level, tools available, and the intended use of the firearm. By weighing these factors, you can make an informed decision and embark on a successful AR-15 lower receiver assembly journey.